Pre-Treatment Systems

- Typically 304 or 316 Stainless Steel wetted parts

- Multiple stage to suit client requirement

- Heated Tanks using Gas or Electric

- Ventilated entry and exit to prevent spray egress

Information

To ensure the best painted surface quality for metals, the pre-treatment prior to painting is essential to improve the adhesion of the paint and improve corrosion resistance. The surface treatment consists of phosphating with Iron or Zinc, Chromating, Oxsilan or Anodizing. Our systems provide a solution for phosphating and similar processes to specific customer requirements.

Surface Prep Automated Wash System for the treatment of parts prior to the coating process. The unit will cycle automatically through various stages to ensure the product is fully cleaned and dried. The unit is capable of carrying out processes that conform to various industrial standards.

Auto Wash Units

Our auto wash units can be designed specificity to suit customer requirements and can be supplied with 2-3-4 stages upwards.

General Construction:

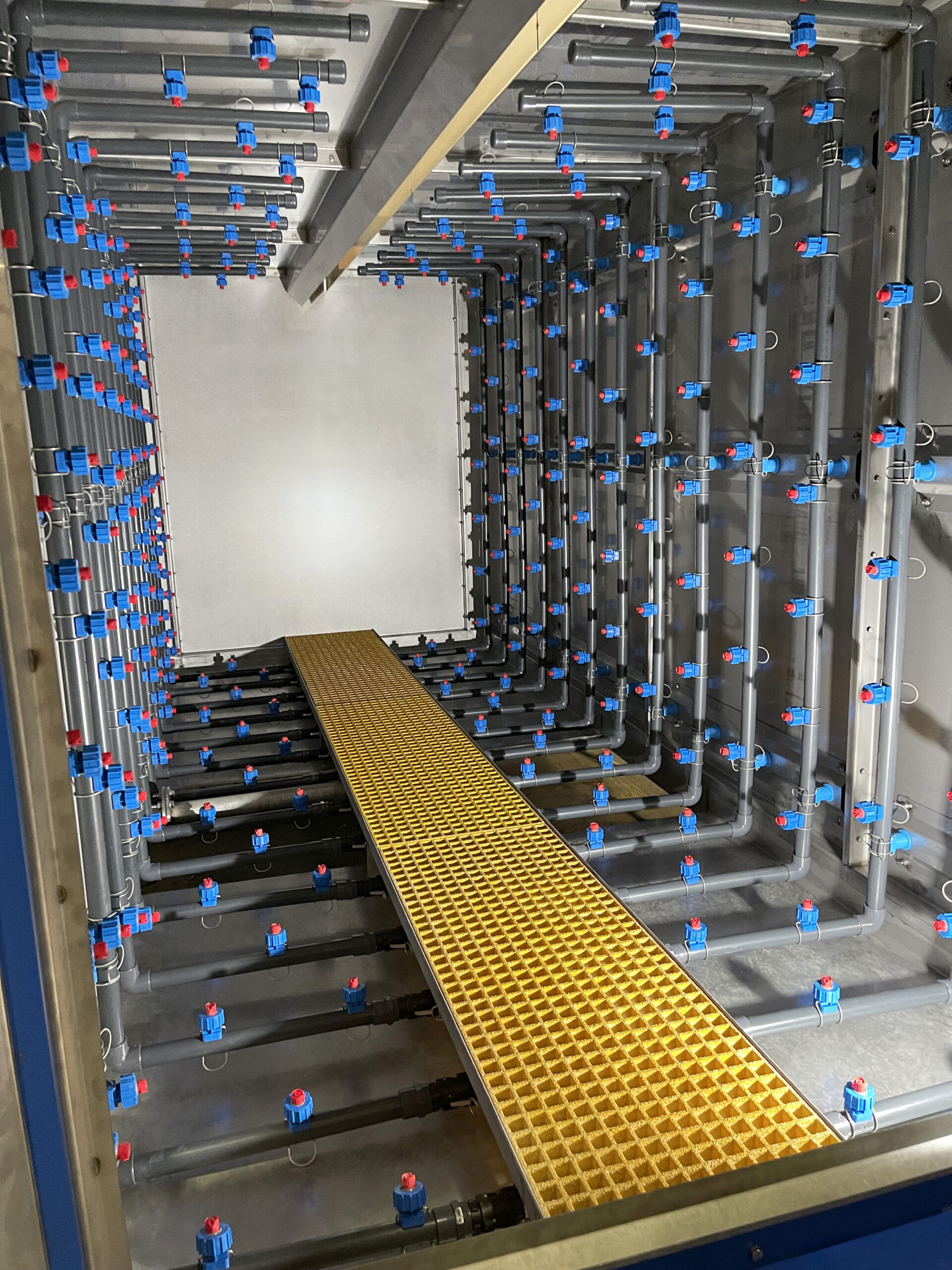

The unit consist of two main structures, the lower collection tank and the upper enclosure.

1. Lower Collection Tank: The lower tank contains the Pre-Treatment solution and is constructed from a 3mm stainless steel water tank, which is fully welded and dye penetrant tested to ensure there are no water leaks. The tank assembly includes a smaller section which houses a ball cock system and a perforated steel filter. This is connected to the re-circulating chemical pump which feeds the chemical spray rings.

2. Upper Enclosure: Stainless steel fabricated enclosure containing the spray rings and hot air plenums used during the drying process. Dye penetrant tested to ensure the unit is leak free.

3. Entrance / Exit Door – An automated vertical rise door will be situated on the front of the unit to allow for product entry / exit. The door will be powered by an electrically driven hoist motor with counterbalance arrangement.

Fume Extraction:

Fume extraction is via the roof mounted plenum. During the treatment cycle the fan will recirculate air within the chamber with a high rate of bleed. This will remove fumes from the enclosure and discharge to atmosphere.

Cleaning Cycle:

A typical cleaning cycle will consist of 3 or more stages all of which occur in the main auto wash chamber

1. Chemical Stage

The cleaner will be applied via spray rings within the main enclosure and will be fed from the main collection tank. The tank will be heated to a temperature of typically 20 – 60 degrees Celsius to enhance the cleaning properties of the solution.

2. Warm Fresh Water Rinse

Following application of the cleaning solution the product will be rinsed with fresh water supplied by a fresh water main feed. This will be heated before applied by the spray rings and will drain to waste.

3. Hot Air Drying

Following the fresh water rinse the product will be dried by high velocity warm air. This will be provided by the roof plenum incorporating a high-performance centrifugal fan and electric heating elements. This warm air will be distributed via wall mounted inlet plenums to create turbulent airflow. A bleed will be taken from the recirculating air stream and discharged to atmosphere to ensure moisture levels in the enclosure remain low, improving drying times.

Control Panel

Control panel, complete with door hardware. Mounted inside the cabinet on a removable panel insert will be a circuit breaker, control relays, interlocks, timer and terminal strips. Mounted on the control panel door will be pushbuttons, indicating lights, programmable controller/timer, and afterburner temperature read-out. The control panel is factory pre-wired.

The control panel will feature the following control interfaces:

Door UP/DOWN

Platen Conveyor IN/OUT

Auto-wash Programme RUN/STOP

PH Readout with Data logging Capability

Data Recorder, Capable of recording: Time/Temp/PH parameters for QA purposes.

Emergency Stop

Audio Visual Alarm (To activate in the event of pre-set temp/time conditions not being met)

https://www.rionews.com.ua/mixed/nonpublicated/now/n23359124748